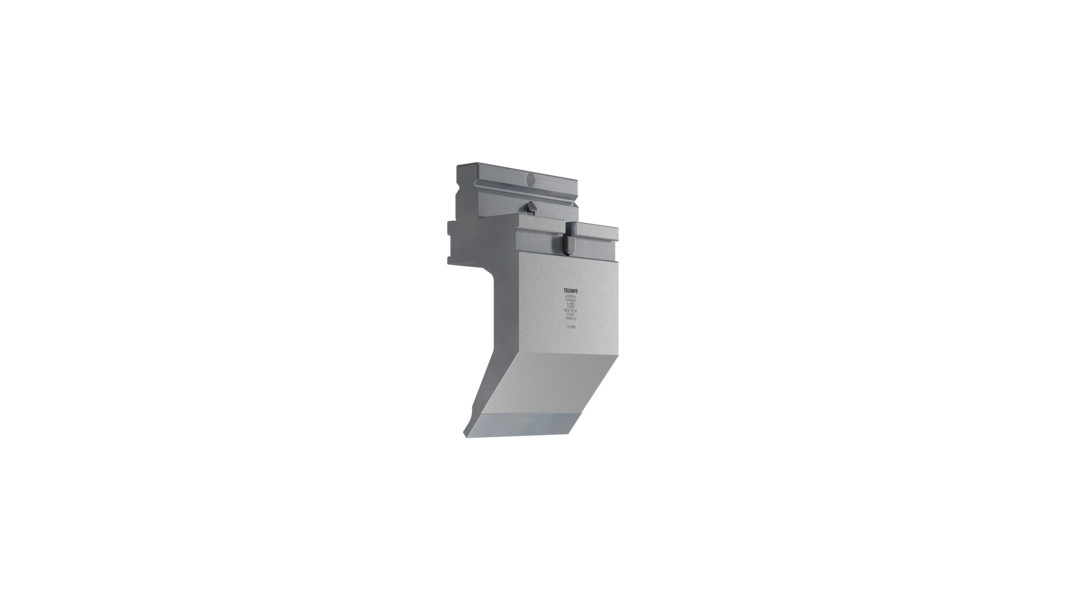

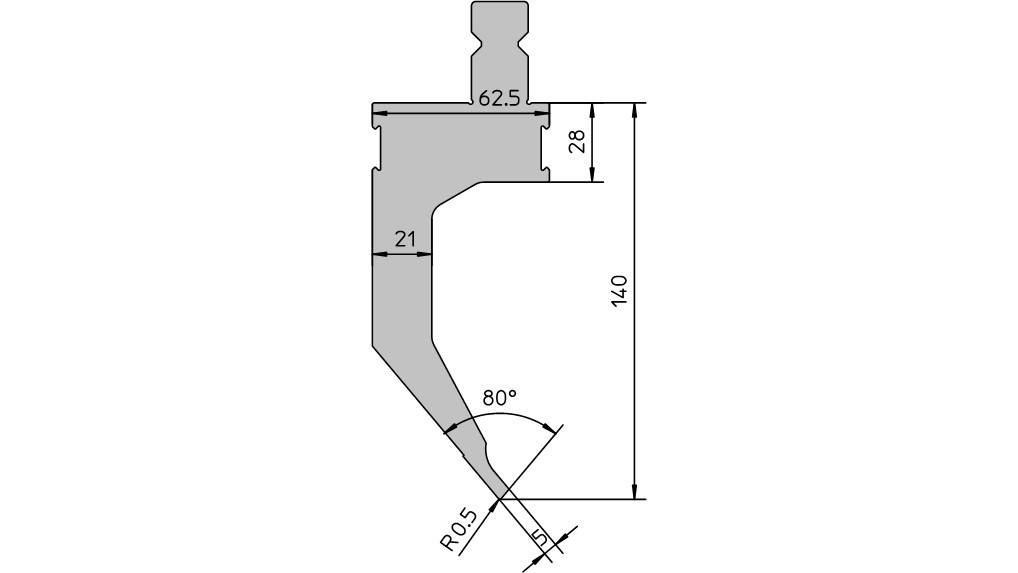

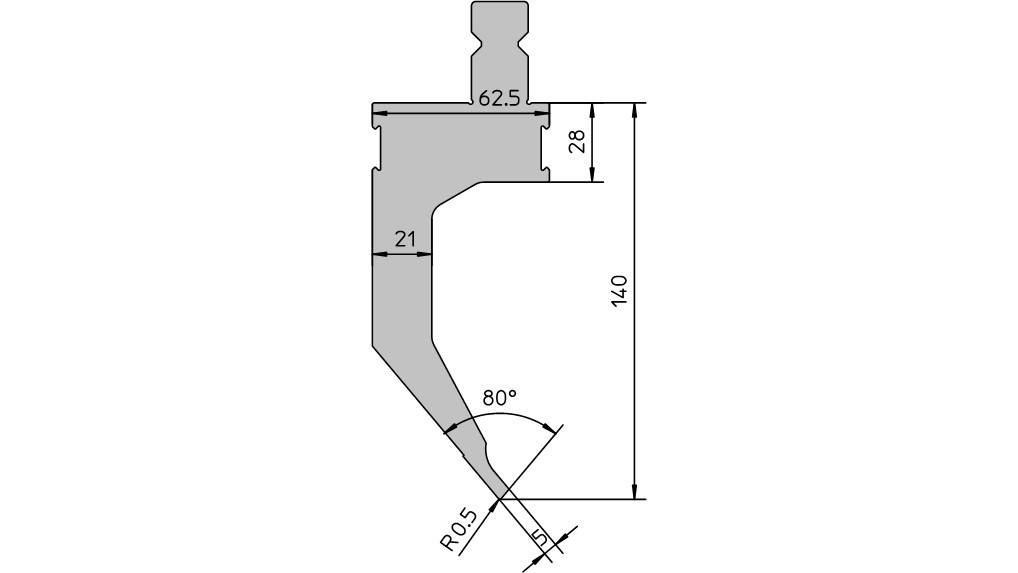

Punch >A< OW280/S

Punch >A< OW280/S

Description

- Suitable for narrow, thin U parts (thin sheets).

Properties of the >A< tools

The >A< tools (automation) differ significantly from the manual tools. It is a completely new tool system.

TIS, the ID chip, provides the intelligence that is responsible for the entire tool change process.

Each individual tool type is recognized in its current position, regardless of where it is (in the machine or in the tool magazine). TIS is therefore used for position and tool type recognition.

A high-precision changing slot and a special click on the tool head guarantee a tool change with process reliability.

The shoulder-bearing design ensures that the tools are positioned with a high level of precision in the machine.

The Safety-Click has an adapted pressure piece length for upper and lower tools. The maximum tool weight for automatic changing is 6 kg, which is why system division A (max. 100 mm pieces) also applies.

In order to minimize the risk of damage to tools and the TIS rail, the >A< tools are rounded at the top.

Shoulder clamping for upper and lower tools: for 25 mm sub-parts <, the tool is designed with a 25 mm long base.

In the case of asymmetrical tools, the slot for the pivoting-jaw gripper is incorporated on both sides.

Technical data

| Compatible with my machines |